|

|

Process manufacturing companies are looking for ways to capture, track, and share increasingly complex process data. At the same time, their supervisory and process control networks must meet robust standards to ensure that their communication and information infrastructure is not compromised. If a system goes down, the result can be millions of dollars in damage, lost production, and dangerous safety issues.

As these companies continue to connect important assets to the network so that they can increase operational transparency, the systems need to scale, and better tools for managing at the edge become essential. A joint effort between OSIsoft and Cisco® is designed to address these needs for real-time process control and efficient data management, focusing on applications in three main industries: power transmission and distribution, oil and gas, and retail. All of these applications are related to the management and utilization of energy.

Industry Trends

• Power: In leading power transmission and distribution companies, OSIsoft and Cisco are working to develop solutions for substation automation and meter data management. This is part of an ongoing trend to respond more quickly to changes in the supply of and demand for energy. These efforts involve upgrading field instrumentation to collect information from remote substations and meters. Once data is collected and analyzed, employees with secure access determine the condition, performance, and utilization of important elements of these complex, interconnected systems. This increases power availability and meets North American Electric Reliability Council (NERC) Critical Infrastructure Protection (CIP) regulatory standards.

• Oil and gas: In the oil and gas industry, OSIsoft and Cisco are exploring applications in brownfield upstream production and pipeline monitoring. These applications are generally geographically dispersed, creating networking challenges for real-time systems. Reducing the hardware requirements and simplifying the administration of these systems allows larger portions of the system to be continuously monitored for trouble, minimizing costly failures.

• Retail: Applications in retail involve monitoring energy consumption and availability at large retailers. This monitoring can substantially increase profits by reducing energy costs. As energy becomes a major expense, companies are looking for innovative ways to control these costs, which otherwise can cripple profitability.

Cisco and OSIsoft Create an Operations Router

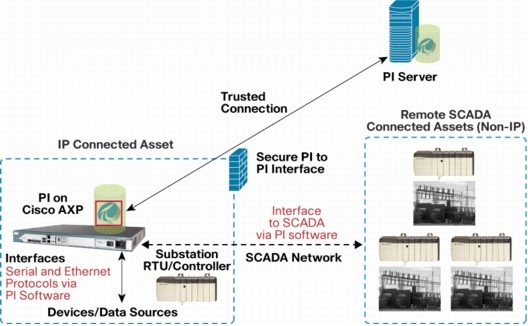

Figure 1. Supervisory Control and Data Acquisition (SCADA) via a Cisco Router with PI Software from OSIsoft

AXP Product Overview

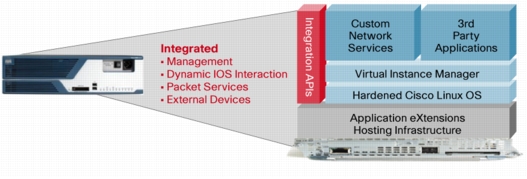

Figure 2. The AXP Environment

• Application runtime network module, providing dedicated resources to host applications

• Application Extension Platform hosting environment, providing the infrastructure to securely host, install, upgrade, and manage third-party applications and services

• Cisco IOS® Software Integration APIs, allowing the application to integrate and utilize the features of the router

• Software developer kit (SDK), allowing certified customers and partners to develop applications and services

• AXP Partner Program, providing collateral, extended technical support, and online resources to help partners develop, deploy, and market their AXP-based solutions

Solution Highlights

• OSIsoft's IT Monitor and Industrial Data Center (IDC), powered by the OSIsoft PI database, are the leading real-time performance management systems for manufacturing industries. The OSIsoft IT Monitor agentless software gathers real-time data-more than 80,000 events per second-from across an entire enterprise without affecting network traffic. This gives decision makers an advanced platform for accurate capacity planning, root cause analysis, and gaining an understanding of how IT assets affect their operations.

• The Cisco Ethernet to the Factory solution helps process manufacturers make the transition from proprietary control networks to standards-based Ethernet. By bridging the gap between the corporate office and control systems, companies can make strategic business decisions that are backed by real-time data.

• The OSIsoft IDC uses the Cisco Business-Ready Data Center architecture, part of the Ethernet to the Factory solution, to help companies monitor and manage their PCNs and business networks. This real-time visibility enables companies to determine when they are one standard deviation beyond normal operating status and to take action before crucial processes or networks go offline. These processes run on an adaptive, integrated, and resilient network with multilayered security. Working together, Cisco and OSIsoft bring industry-leading expertise to bear on a growing problem to corporate clients everywhere.

Business Benefits

• Have a 360-degree view of plant operations to enable troubleshooting and predictive analysis without compromising network performance or network security

• Anticipate problems and minimize disruptions to operations networks

• Troubleshoot problems with greater precision to reduce mean time to repair

• Eliminate silos of information that result in duplication of effort, miscommunication, and lack of accountability

• Share and manage information over a converged network

• Create a more collaborative operations environment to shorten lead times and respond quickly to customers

• Support "just-in-time" customer processes to reduce costs, waste, and inventory

About OSIsoft