Feedback Feedback

|

Table Of Contents

Alarm Interface Controller Patch Panel Installation Guide

Mounting the Strain Relief Bar

Obtaining Technical Assistance

Alarm Interface Controller Patch Panel Installation Guide

AIC-SGL-PNL(=), AIC-DBL-PNL(=)

This guide describes how to install the alarm interface controller (AIC) patch panel and how to connect it to the AIC network module for Cisco 2600 series, Cisco 3640, and Cisco 3660 modular access routers and the Cisco MWR 1941-DC Mobile Wireless Edge Router. It contains the following sections:

•

Obtaining Technical Assistance

Use this document with the documents listed in "Related Documents" section

Overview

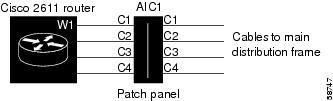

The patch panel supplies power to the alarm circuits connected to an AIC network module, by means of a -48V DC circuit bridged to the alarm circuit. Current flows when the loop is closed by an alarm. The network module detects this current and sends a message to the network operating center.

There are two models of AIC patch panel:

•

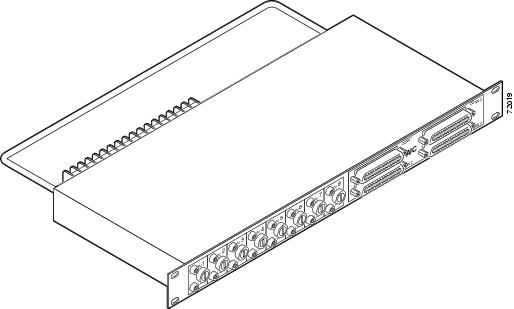

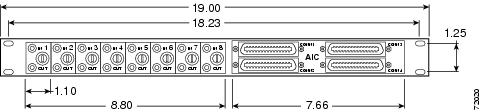

Product number AIC-SGL-PNL (see Figure 1, Figure 2, and Figure 3) connects to a single AIC network module. It provides an interface between a bank of four Telco 50-pin connectors (for the Telco side) and a bank of four 50-pin SCSI II connectors (for the network module side).

•

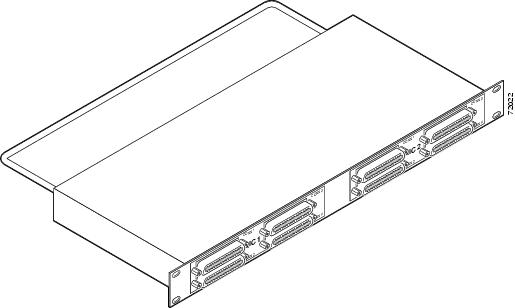

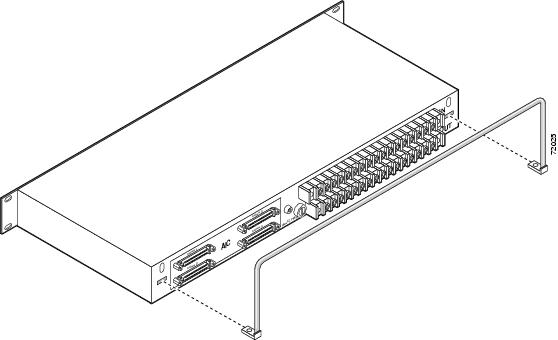

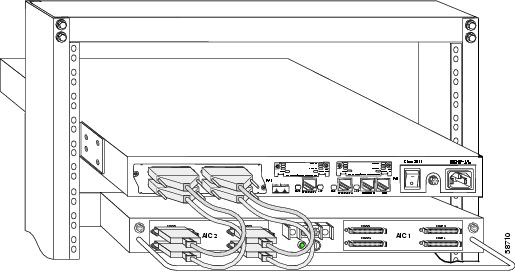

Product number AIC-DBL-PNL (see Figure 4, Figure 5, and Figure 6) connects to two AIC network modules. It provides an interface between two banks of four Telco 50-pin) connectors and two banks of four SCSI II connectors.

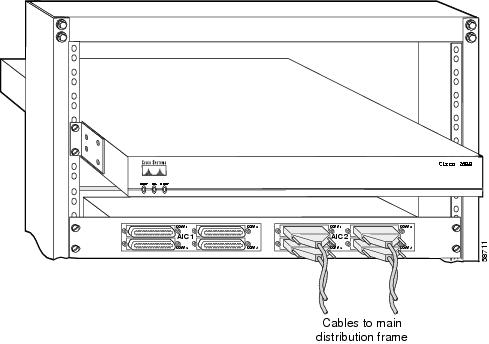

The AIC network module is shown in Figure 7.

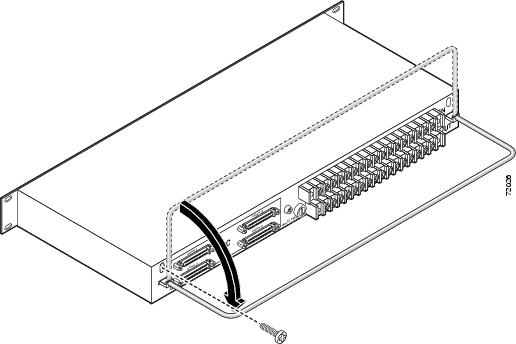

Figure 1 AIC-SGL-PNL Patch Panel

Figure 2 AIC-SGL-PNL Patch Panel Dimensions and Front View

Figure 3 AIC-SGL-PNL Patch Panel, Rear View

Figure 4 AIC-DBL-PNL Patch Panel

Figure 5 AIC-DBL-PNL Patch Panel, Front View

Figure 6 AIC-DBL-PNL Patch Panel, Rear View

Figure 7 Alarm Interface Controller Network Module

Table 1 gives temperature specifications for the patch panel.

Safety Information

Read the following safety information before performing any installation or connection procedure.

Warning

This unit is intended for installation in restricted access areas. A restricted access area is one where access can be gained by service personnel only through the use of a special tool, lock and key, or other means of security, and is controlled by the authority responsible for the location. To see translations of the warnings that appear in this publication, refer to the Regulatory Compliance and Safety Information document that accompanied this device.

Warning

To prevent bodily injury when mounting or servicing this unit in a rack, you must take special precautions to ensure that the system remains stable. The following guidelines are provided to ensure your safety:

•

This unit should be mounted at the bottom of the rack if it is the only unit in the rack.

•

When mounting this unit in a partially filled rack, load the rack from the bottom to the top with the heaviest component at the bottom of the rack.

•

If the rack is provided with stabilizing devices, install the stabilizers before mounting or servicing the unit in the rack.

Warning

This product relies on the building's installation for short-circuit (overcurrent) protection. Ensure that a UL Listed and Certified fuse or circuit breaker no larger than 60 VDC, 15 A is used on all current-carrying conductors. To see translations of the warnings that appear in this publication, refer to the Regulatory Compliance and Safety Information document that accompanied this device.

CautionTo prevent the patch panel from overheating, do not operate it in an area that exceeds the maximum recommended ambient temperature of 104°F (40°C). If installed in a closed or multiunit rack assembly, the operating ambient temperature of the rack environment may be greater than room ambient. To prevent airflow restriction, allow at least 6 in. (15 cm) of clearance around the ventilation openings.

Warning

Damage to the AIC network module can occur if an alarm set for monitoring current is connected to a sensor for monitoring voltage. Make sure that your alarms are connected to the proper sensors. To see translations of the warnings that appear in this publication, refer to the Regulatory Compliance and Safety Information document that accompanied this device.

CautionConnect the cable to the AIC before connecting it to the patch panel or other connection. Otherwise voltage could be present on the male pins which connect to the AIC.

CautionThe signal I/O connections on this unit are intended only for connection to NEC/CEC Class 2 or equivalent circuit. This means that the voltages applied to I/O connections should not exceed

42.4 Vpk or 60 Vdc and it should be limited/fused power source. For more details on Class 2 circuits, refer to the National Electrical Code/Canadian Electrical Code. This does not apply to analog input/output terminal strip numbers 1-8 on the AIC-SGL-PNL patch panel.

CautionThis unit is not intended for connection to exposed plant leads. Therefore, it should not be connected to circuit conductors, which extend beyond one building and are run so as to be subject to accidental contact with AC main conductors, or are exposed to lightning on interbuilding circuits on the same premises.

CautionThe BAT terminal receives negative voltage, and the RET terminal receives positive voltage.

CautionAll circuits in the patch panel are safety extra-low voltage (SELV) circuits. SELV circuits should be connected only to other SELV circuits.

Required Tools and Equipment

Installation might require some tools and equipment that are not provided as standard equipment with the router. Following are the tools and parts required for a typical installation:

•

Number 2 Phillips screwdriver

•

ESD-preventive wrist strap

Mounting the Patch Panel

You can mount the patch panel in a 19-inch rack using the built-in brackets.

Mounting the Strain Relief Bar

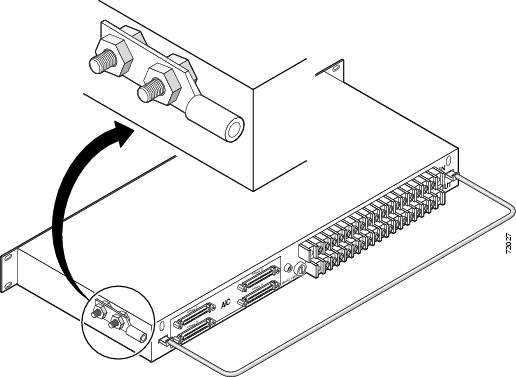

Mount the strain relief bar as shown in Figure 8 and Figure 9.

Figure 8 Inserting the Strain Relief Bar

Figure 9 Positioning the Strain Relief Bar

Electrical Connections

This section explains how to ground the patch panel and how to connect electrical power.

Grounding

The patch panel comes with a grounding lug preinstalled. To ground the lug, follow these steps:

Step 1

Make sure that power to the patch panel is off, and that no cables are connected.

Warning

Before performing any of the following procedures, ensure that power is removed from the DC circuit. To ensure that all power is OFF, locate the circuit breaker on the panel board that services the DC circuit, switch the circuit breaker to the OFF position, and tape the switch handle of the circuit breaker in the OFF position. To see translations of the warnings that appear in this publication, refer to the Regulatory Compliance and Safety Information document that accompanied this device.

Step 2

Remove the two outside 8-32 nuts attached to the patch panel chassis and and the grounding lug and put them aside (see Figure 10).

Figure 10 Grounding Lug

Step 3

Strip one end of an AWG 6 copper wire to expose approximately 0.75 in. (20 mm).

Step 4

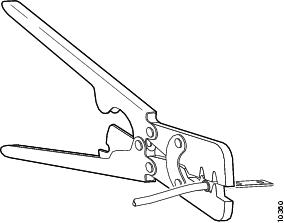

Place the wire in the lug. Using a Panduit CT-720 crimp tool with die set CD-720-2, or the equivalent, crimp the lug until the wire is firmly in place, as shown in Figure 11.

Figure 11 Crimping the Lug Around the Wire

Step 5

Fit the grounding lug over the bolt posts on top of the two inside 8-32 nuts.

Step 6

Hand tighten the outside 8-32 nuts on the bolt posts on top of the grounding lug (see Figure 10).

CautionDo not overtorque the outside 8-32 nuts. The recommended torque is 15 ± 18 inch-lb.

Step 7

Connect the other end of the wire to a suitable grounding point.

Connecting Electrical Power

This section explains how to connect electrical power to the patch panel.

The AIC-SGL-PNL patch panel provides terminals for eight analog circuits. Power is provided to each monitored circuit by the IN terminal block on the back of the patch panel. Power is taken from each monitored circuit by the OUT terminal block located below the IN terminal block.

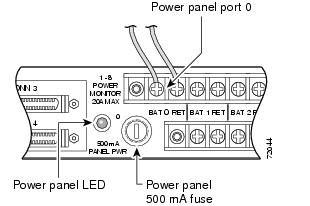

The AIC-SGL-PNL patch panel must also have -48 VDC connected to the first pair of terminals (port 0) on the IN terminal block. This voltage is independent of other feeds being monitored and is used to operate the detection circuits. The 500 mA fuse for port 0 is shown in Figure 12.

The AIC-DBL-PNL patch panel does not provide monitoring of analog circuits. This patch panel must have -48 VDC connected to the terminal block on the back of the patch panel.

Follow this procedure to wire the terminal block:

Warning

Before connecting or disconnecting ground or power wires to the chassis, ensure that power is removed from the DC circuit. To ensure that all power is OFF, locate the circuit breaker on the panel board that services the DC circuit, switch the circuit breaker to the OFF position, and tape the switch handle of the circuit breaker in the OFF position. To see translations of the warnings that appear in this publication, refer to the Regulatory Compliance and Safety Information document that accompanied this device.

Step 1

Make sure that you have grounded the patch panel, as described in the"Grounding" section.

Step 2

Attach lugs to 14-AWG (1.5 mm2 cross section) copper wire or equivalent.

Step 3

If you are connecting an AIC-SGL-PNL patch panel, connect wires from the monitored analog circuits to terminal blocks 1 through 8 on the back panel. The BAT (negative) terminal is on the left and the RET (positive) terminal is on the right of each pair, as you look at the back of the patch panel. BAT and RET are also marked on the patch panel chassis. Labels identify the port numbers.

Step 4

Connect -48 VDC to port 0 on the back of the AIC-SGL-PNL patch panel, or to the terminal block on the back of the AIC-DBL-PNL patch panel. The BAT (negative) terminal is on the left and the RET (positive) terminal is on the right of each pair, as you look at the back of the patch panel. BAT and RET are also marked on the patch panel chassis. See Figure 12.

Figure 12 -48 VDC Connection

Warning

When stranded wiring is required, use approved wiring terminations, such as closed-loop or spade-type with upturned lugs. These terminations should be the appropriate size for the wires and should clamp both the insulation and conductor. To see translations of the warnings that appear in this publication, refer to the Regulatory Compliance and Safety Information document that accompanied this device.

CautionDo not overtorque the terminal block terminal block contact screws. The recommended torque is

8.2 ± 0.4 inch-lb.

Warning

An exposed wire lead from a DC-input power source can conduct harmful levels of electricity. Be sure that no exposed portion of the DC-input power source wire extends from the terminal block plug. To see translations of the warnings that appear in this publication, refer to the Regulatory Compliance and Safety Information document that accompanied this device.

Warning

Secure all power cabling when installing this unit to avoid disturbing field-wiring connections. To see translations of the warnings that appear in this publication, refer to the Regulatory Compliance and Safety Information document that accompanied this device.

Warning

After reinstating the DC power, remove the tape from the circuit breaker switch handle and reinstate power by moving the handle of the circuit breaker to the ON position. To see translations of the warnings that appear in this publication, refer to the Regulatory Compliance and Safety Information document that accompanied this device.

Connecting Network Cables

Patch panel connections to the AIC network module are shown schematically in Figure 13. The four connectors of each AIC network module connect to four input connectors on the patch panel. The output connectors of the patch panel are cabled to the customer's main distribution frame (MDF). The patch panel looks transparent to the AIC network module.

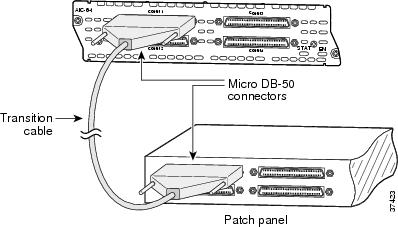

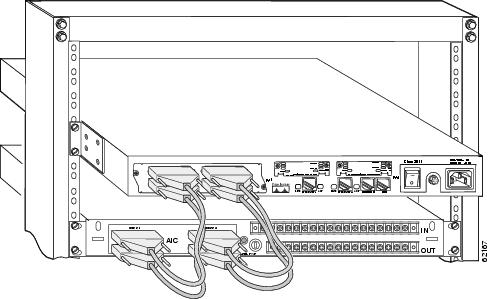

An AIC network module provides four interfaces using 50-pin SCSI II receptacles. To connect the

SCSI II connectors on the front of the patch panel to the network module, use cables that have male Micro DB-50 connectors at both ends, with all conductors straight-wired. A set of four eight-foot male-to-male SCSI II interface cables is orderable separately, product number CAB-AIC-008. Ports are numbered from right to left and from bottom to top, as labeled on the module's rear panel (see Figure 7).To connect the Telco connectors on the back of the patch panel to the main distribution frame, use RJ-21 Telco connector serial cables (50-pin male).

Figure 14 shows connections from the AIC network module faceplate to a patch panel. Figure 15 shows connections to the AIC-SGL-PNL patch panel. Figure 16 shows connections to the AIC-DBL-PNL patch panel.

Figure 17 shows patch panel connections to the main distribution frame. These connections should be made with AWG 24 copper wire or equivalent.

Figure 13 AIC Network Module Connection Diagram

Figure 14 AIC Network Module Faceplate Connections

Figure 15 AIC Network Module Connected to the AIC-SGL-PNL Patch Panel

Figure 16 AIC Network Module Connected to the AIC-DBL-PNL Patch Panel

Figure 17 AIC-DBL-PNL Patch Panel Connected to MDF

Patch Panel LEDs

Each monitored analog circuit on the AIC-SGL-PNL patch panel has a green POWER IN LED and a green POWER OUT LED on the front of the patch panel. The POWER IN LED is on when voltage is present before the fuse. The POWER OUT LED is on when voltage is present after the fuse. See Figure 18.

Figure 18 Patch Panel LEDs and Fuses

Both models of patch panel have a green PANEL POWER LED on the back. This LED shows the status of the -48 VDC input used to operate the detection circuits.

Patch Panel Pinouts

Table 2 shows pinouts for the AIC-SGL-PNL patch panel. Table 3 shows connector 3 voltage monitor pinouts for the AIC-SGL-PNL patch panel. Table 4 shows pinouts for the AIC-DBL-PNL patch panel.

Table 2 AIC-SGL-PNL Patch Panel Connector Pinouts

1

Alarm neg1

Alarm neg 26

Alarm neg 51

Control common 1

26

Alarm pos 1

Alarm pos 26

Alarm pos 51

Control N.O. 1

2

Alarm neg 2

Alarm neg 27

Alarm neg 52

Control common 2

27

Alarm pos 2

Alarm pos 27

Alarm pos 52

Control N.O. 2

3

Alarm neg 3

Alarm neg 28

Alarm neg 53

Control common 3

28

Alarm pos 3

Alarm pos 28

Alarm pos 53

Control N.O. 3

4

Alarm neg 4

Alarm neg 29

Alarm neg 54

Control common 4

29

Alarm pos 4

Alarm pos 29

Alarm pos 54

Control N.O. 4

5

Alarm neg 5

Alarm neg 30

Alarm neg 55

Control common 5

30

Alarm pos 5

Alarm pos 30

Alarm pos 55

Control N.O. 5

6

Alarm neg 6

Alarm neg 31

Alarm neg 56

Control common 6

31

Alarm pos 6

Alarm pos 31

Alarm pos 56

Control N.O. 6

7

Alarm neg 7

Alarm neg 32

See Table 3

Control common 7

32

Alarm pos 7

Alarm pos 32

See Table 3

Control N.O. 7

8

Alarm neg 8

Alarm neg 33

See Table 3

Control common 8

33

Alarm pos 8

Alarm pos 33

See Table 3

Control N.O. 8

9

Alarm neg 9

Alarm neg 34

See Table 3

Control common 9

34

Alarm pos 9

Alarm pos 34

See Table 3

Control N.O. 9

10

Alarm neg 10

Alarm neg 35

See Table 3

Control common 10

35

Alarm pos 10

Alarm pos 35

See Table 3

Control N.O. 10

11

Alarm neg 11

Alarm neg 36

See Table 3

Control common 11

36

Alarm pos 11

Alarm pos 36

See Table 3

Control N.O. 11

12

Alarm neg 12

Alarm neg 37

See Table 3

Control common 12

37

Alarm pos 12

Alarm pos 37

See Table 3

Control N.O. 12

13

Alarm neg 13

Alarm neg 38

See Table 3

Control common 13

38

Alarm pos 13

Alarm pos 38

See Table 3

Control N.O. 13

14

Alarm neg 14

Alarm neg 39

See Table 3

Control common 14

39

Alarm pos 14

Alarm pos 39

See Table 3

Control N.O. 14

15

Alarm neg 15

Alarm neg 40

—

Control common 15

40

Alarm pos 15

Alarm pos 40

—

Control N.O. 15

16

Alarm neg 16

Alarm neg 41

—

Control common 16

41

Alarm pos 16

Alarm pos 41

—

Control N.O. 16

17

Alarm neg 17

Alarm neg 42

—

—

42

Alarm pos 17

Alarm pos 42

—

—

18

Alarm neg 18

Alarm neg 43

—

—

43

Alarm pos 18

Alarm pos 43

—

—

19

Alarm neg 19

Alarm neg 44

—

—

44

Alarm pos 19

Alarm pos 44

—

—

20

Alarm neg 20

Alarm neg 45

—

—

45

Alarm pos 20

Alarm pos 45

—

—

21

Alarm neg 21

Alarm neg 46

—

—

46

Alarm pos 21

Alarm pos 46

—

—

22

Alarm neg 22

Alarm neg 47

—

—

47

Alarm pos 22

Alarm pos 47

—

—

23

Alarm neg 23

Alarm neg 48

—

—

48

Alarm pos 23

Alarm pos 48

—

—

24

Alarm neg 24

Alarm neg 49

—

—

49

Alarm pos 24

Alarm pos 49

—

—

25

Alarm neg 25

Alarm neg 50

—

—

50

Alarm pos 25

Alarm pos 50

—

—

Related Documents

For additional information, see the following documents:

•

Cisco 2600 Series Hardware Installation Guide

•

Cisco 3600 Series Hardware Installation Guide

•

Cisco MWR 1941-DC Mobile Wireless Edge Router Hardware Installation Guide

•

Cisco Network Module Hardware Installation Guide

•

Software Configuration Guide for Cisco 3600 Series and Cisco 2600 Series Routers

•

Cisco MWR 1941-DC Mobile Wireless Edge Router Software Configuration Guide

•

Regulatory Compliance and Safety Information for the Cisco 2600 and Cisco 3600 Series

•

Regulatory Compliance and Safety Information for the Cisco MWR 1941-DC Mobile Wireless Edge Router

•

Quick Start Guide for your router

Obtaining Documentation

The following sections explain how to obtain documentation from Cisco Systems.

World Wide Web

You can access the most current Cisco documentation on the World Wide Web at the following URL:

Translated documentation is available at the following URL:

http://www.cisco.com/public/countries_languages.shtml

Ordering Documentation

Cisco documentation is available in the following ways:

•

Registered Cisco Direct Customers can order Cisco product documentation from the Networking Products MarketPlace:

http://www.cisco.com/cgi-bin/order/order_root.pl

•

Registered Cisco.com users can order the Documentation CD-ROM through the online Subscription Store:

http://www.cisco.com/go/subscription

•

Nonregistered Cisco.com users can order documentation through a local account representative by calling Cisco corporate headquarters (California, USA) at 408 526-7208 or, elsewhere in North America, by calling 800 553-NETS (6387).

Documentation Feedback

If you are reading Cisco product documentation on Cisco.com, you can submit technical comments electronically. Click Leave Feedback at the bottom of the Cisco Documentation home page. After you complete the form, print it out and fax it to Cisco at 408 527-0730.

You can e-mail your comments to bug-doc@cisco.com.

To submit your comments by mail, use the response card behind the front cover of your document, or write to the following address:

Cisco Systems

Attn: Document Resource Connection

170 West Tasman Drive

San Jose, CA 95134-9883We appreciate your comments.

Obtaining Technical Assistance

Cisco provides Cisco.com as a starting point for all technical assistance. Customers and partners can obtain documentation, troubleshooting tips, and sample configurations from online tools by using the Cisco Technical Assistance Center (TAC) Web Site. Cisco.com registered users have complete access to the technical support resources on the Cisco TAC Web Site.

Cisco.com

Cisco.com is the foundation of a suite of interactive, networked services that provides immediate, open access to Cisco information, networking solutions, services, programs, and resources at any time, from anywhere in the world.

Cisco.com is a highly integrated Internet application and a powerful, easy-to-use tool that provides a broad range of features and services to help you to

•

Streamline business processes and improve productivity

•

Resolve technical issues with online support

•

Download and test software packages

•

Order Cisco learning materials and merchandise

•

Register for online skill assessment, training, and certification programs

You can self-register on Cisco.com to obtain customized information and service. To access Cisco.com, go to the following URL:

Technical Assistance Center

The Cisco TAC is available to all customers who need technical assistance with a Cisco product, technology, or solution. Two types of support are available through the Cisco TAC: the Cisco TAC Web Site and the Cisco TAC Escalation Center.

Inquiries to Cisco TAC are categorized according to the urgency of the issue:

•

Priority level 4 (P4)—You need information or assistance concerning Cisco product capabilities, product installation, or basic product configuration.

•

Priority level 3 (P3)—Your network performance is degraded. Network functionality is noticeably impaired, but most business operations continue.

•

Priority level 2 (P2)—Your production network is severely degraded, affecting significant aspects of business operations. No workaround is available.

•

Priority level 1 (P1)—Your production network is down, and a critical impact to business operations will occur if service is not restored quickly. No workaround is available.

Which Cisco TAC resource you choose is based on the priority of the problem and the conditions of service contracts, when applicable.

Cisco TAC Web Site

The Cisco TAC Web Site allows you to resolve P3 and P4 issues yourself, saving both cost and time. The site provides around-the-clock access to online tools, knowledge bases, and software. To access the Cisco TAC Web Site, go to the following URL:

All customers, partners, and resellers who have a valid Cisco services contract have complete access to the technical support resources on the Cisco TAC Web Site. The Cisco TAC Web Site requires a Cisco.com login ID and password. If you have a valid service contract but do not have a login ID or password, go to the following URL to register:

http://www.cisco.com/register/

If you cannot resolve your technical issues by using the Cisco TAC Web Site, and you are a Cisco.com registered user, you can open a case online by using the TAC Case Open tool at the following URL:

http://www.cisco.com/tac/caseopen

If you have Internet access, it is recommended that you open P3 and P4 cases through the Cisco TAC Web Site.

Cisco TAC Escalation Center

The Cisco TAC Escalation Center addresses issues that are classified as priority level 1 or priority level 2; these classifications are assigned when severe network degradation significantly impacts business operations. When you contact the TAC Escalation Center with a P1 or P2 problem, a Cisco TAC engineer will automatically open a case.

To obtain a directory of toll-free Cisco TAC telephone numbers for your country, go to the following URL:

http://www.cisco.com/warp/public/687/Directory/DirTAC.shtml

Before calling, please check with your network operations center to determine the level of Cisco support services to which your company is entitled; for example, SMARTnet, SMARTnet Onsite, or Network Supported Accounts (NSA). In addition, please have available your service agreement number and your product serial number.

CCIP, CCSP, the Cisco Arrow logo, the Cisco Powered Network mark, Cisco Unity, Follow Me Browsing, FormShare, and StackWise are trademarks of Cisco Systems, Inc.; Changing the Way We Work, Live, Play, and Learn, and iQuick Study are service marks of Cisco Systems, Inc.; and Aironet, ASIST, BPX, Catalyst, CCDA, CCDP, CCIE, CCNA, CCNP, Cisco, the Cisco Certified Internetwork Expert logo, Cisco IOS, the Cisco IOS logo, Cisco Press, Cisco Systems, Cisco Systems Capital, the Cisco Systems logo, Empowering the Internet Generation, Enterprise/Solver, EtherChannel, EtherSwitch, Fast Step, GigaStack, Internet Quotient, IOS, IP/TV, iQ Expertise, the iQ logo, iQ Net Readiness Scorecard, LightStream, MGX, MICA, the Networkers logo, Networking Academy, Network Registrar, Packet, PIX, Post-Routing, Pre-Routing, RateMUX, Registrar, ScriptShare, SlideCast, SMARTnet, StrataView Plus, Stratm, SwitchProbe, TeleRouter, The Fastest Way to Increase Your Internet Quotient, TransPath, and VCO are registered trademarks of Cisco Systems, Inc. and/or its affiliates in the U.S. and certain other countries.

All other trademarks mentioned in this document or Web site are the property of their respective owners. The use of the word partner does not imply a partnership relationship between Cisco and any other company. (0304R)

Copyright © 2002-2003, Cisco Systems, Inc. All rights reserved.

Printed in the USA on recycled paper containing 10% postconsumer waste.