Today, equipment can become quickly obsolete. We aim to reduce the amount of waste generated from our products by designing our equipment for modularity, upgradeability, refurbishment, and reuse and by encouraging customers to recycle end-of-life equipment through take-back programs.

Before any Cisco product is made, our engineers consider what will happen at the end of its useable life. Extending useable life reduces the need for replacements, decreasing demand for resources and reducing waste. The modular design of our products means that new versions are compatible with previous versions, enabling users to upgrade certain components while retaining others. Designing products for easy disassembly also facilitates reuse or recycling of components.

When products reach end of life, our reverse logistics programs offer customers the option to return them for reuse or recycling. In FY10, we collected 8580 metric tonnes of products, 13 percent of which were refurbished for reuse.

The Cisco Technology Migration Program offers discounts on new products when a customer trades in a functioning product. These are wiped clean of data and either sold again or redeployed by Cisco. Our TakeBack and Recycle Program offers customers the opportunity to return older or broken equipment that cannot be reused.

The products that are sent to recycling facilities are demanufactured and broken down into their constituent fraction commodities such as steel, aluminum, copper, cardboard, plastic, shredded printed circuit boards, and wire and cable. These are sold to downstream recyclers to be made into other products and Cisco receives a share of the revenue. The redeployment of the traded-in products and the revenue share generated from the sale of recycling fractions totaled $203 million for Cisco in FY10.

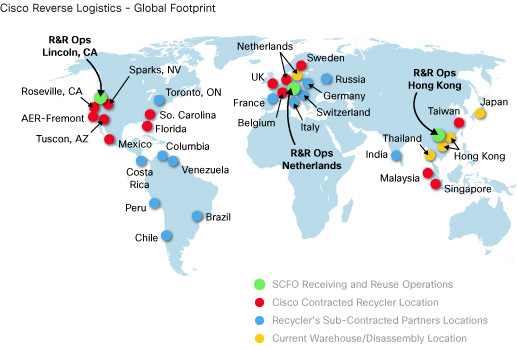

The electronic waste we collect is channeled through four select global ISO-14001 certified recycling partners. They are contractually required to ensure that their subcontractors also follow our strict requirements. Our recycling partners report the weight of materials submitted before and after shipping to check that nothing goes missing along the way. From this, we can calculate the proportion of material that is recycled.

In FY10, we reused or recycled all electronic equipment returned to us. Only 0.333 percent of waste collected was made up of nonrecycleable materials that were sent to landfill (such as broken pallets, wet cardboard, and shrink wrap from packaging).

As our business expands in emerging markets, we will work with industry peers and regional leaders to ensure that adequate facilities are available for collection, recycling, and disposal of e-waste. In FY10, we extended our TakeBack and Recycle Program globally and continued to build our network of local recycling partners, with new subcontractors in Costa Rica and Russia.